Contamination in process water and operating fluids contribute to the wear of system components, pipelines, and valves. It also harms the quality of end products. Manufacturers can improve their system lifetime and the quality of their end products by installing automatic filters into their systems. Filtration systems protect operational infrastructure and guarantee short maintenance times by removing solid particles from operating fluids. Automatic back-flushing filters provide additional advantages with their fully-automatic operation and ready-to-operate design.

HYDAC has been engineering and manufacturing automatic, self-cleaning filters since the 1980s. They maintain high quality and environmental management standards, adhering to DIN EN ISO 9001 and DIN EN ISO 14001. Their range of automatic filters, AutoFilt®, has been highly successful in process technology thanks to their flow-optimized, robust design.

>Benefits of using automatic filters from the AutoFilt® series:

- Cleanable filter materials

- Longer service life for components further downstream

- Less energy consumption

- Improved process reliability

- Proven quality

Support from a Trusted ESV

As an engineering partner, systems integrator, and value-added distributor (ESV), Evolution can help you select the proper automatic back-flushing filter for your system and properly size the filter elements. We work alongside your maintenance or engineering teams to gather a complete understanding of how your system works so we can optimize your automatic filter system. Our qualified engineering and sales teams can assist in commissioning your new back-flushing filter to ensure your retrofitting process goes smoothly.

Intelligent Filter Element Technology

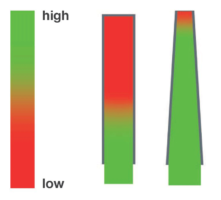

Evolution and HYDAC understand that filter elements can be a determining factor when evaluating a system’s performance. The conical shape of the filter elements used in the AutoFilt® series supports consistent flow through the filter element, which results in a low-pressure drop and cleaning of the filter element. See savings in filter element replacements and reduced downtime with the cleanable filter elements from HYDAC.

The conical elements are available as wedge wire or SuperMesh types. SuperMesh filter elements from HYDAC have exceptional stability thanks to sintered element technology. Their design makes them highly effective for cleaning, avoiding particle build-up between the layers of the filter element. The SuperMesh elements have a self-supporting structure, which allows them to be up to 40% larger than their wire mesh counterparts with a support layer.

For additional non-stick coating on your filter elements, choose HYDAC’s SuperFlush option. This unique coating technology is available for almost all filter element types of the AutoFilt® series and is recommended for filtration ratings < 200 µm. SuperFlush reduces the adhesion of sticky particles on a filter element. This reduces biofouling, increases efficiency, and increases the intervals between back-flush cycles.

Efficiency of conical elements

Automatic Back-Flushing Filter AutoFilt® RF3

The flow-optimized design of the AutoFilt® RF3 allows for the maximum utilization of the filter area to separate solid particles from low-viscosity fluids. Automatic back-flushing is triggered by exceeding the differential pressure point, using a set timer function, or manually pressing a “Test” button. It is fully automatic in operation, including process monitoring and self-diagnosis. The easy-to-view and easy-to-use AutoFilt® Control Unit (ACU) allows users to monitor operations at all times. Users can take advantage of remote monitoring via their smartphone or tablet.

- Open connectivity to common interfaces

- Bidirectional communication of component activity

Industry Example

Application Example

Power Plants

- Industrial water conditioning

- Sealing water filtration to increase the lifetime of turbine floating ring seals

Steel Industry

- Process water filtration to protect the nozzles and pumps used in high-pressure descaling

- Conditioning of water used for cooling blast furnaces and rolling mills

- Emulsion filtration in hot and cold rolling mills

- Rolling emulsion filtration

Paper Industry

- Protect nozzles on paper machines

- Freshwater treatment used for cooling

Automotive Industry

- Cooling lubricant filtration

- Washing fluids filtration

- Machine tools protection

Chemical Industry

- Cooling water filtration

- Wastewater filtration

- Machine tool protection

Oil and Gas Industry

- Injection water filtration

- Cooling water filtration

- Service water filtration

- Flushing water filtration

Water and Waste Water Treatment

- Protective filters ahead of membrane systems

- Service water conditioning

Automatic Back-Flushing Filter AutoFilt® RF4

The AutoFilt® RF4 is a compact automatic back-flushing filter from HYDAC that removes particles from low-viscosity fluids such as coolants and water. Its back flush is triggered automatically when the differential pressure trigger point is exceeded, but it can also be triggered manually when the visual clogging indicator responds. The RF4 is fully automatic in operation and ready to operate. The RF4 has built-in self-diagnosis and process monitoring with optional remote monitoring via smartphone or tablet.

- Bidirectional communication of component activity

- Open connectivity to common interfaces

Industry Example

Application Example

Automotive Industry, Machine Tools

- Cooling lubricant and washing fluid filtration

- Protect cooling channels, pipelines, rotary joints, and valves from wear and clogging

Power Plants

- Industrial water conditioning

- Sealing water filtration to increase the lifetime of turbine floating ring seals

Paper Industry

- Protect nozzles on paper machines

- Freshwater treatment used for cooling

Water and Waste Water Treatment

- Protective filters ahead of membrane systems

- Service water conditioning

Automatic Back-Flushing Filter AutoFilt® RF5

The AutoFilt® RF5 from HYDAC is built with proven technology and a vertical filter inlet. Its sturdy construction and automatic back-flushing capabilities contribute to operational reliability and reduced maintenance and operating costs. Automatic back-flushing is triggered by exceeding the differential pressure trigger point, using a set timer, or manually pressing the “Test” button. The RF5 is a fully automatic, ready-to-operate unit for applications with flow rates up to 4200 m3/h.

Industry Example

Application Example

Power Plants

- Industrial water conditioning

- Sealing water filtration to increase the lifetime of the turbine floating ring seals

Paper Industry

- Protect the nozzles on the paper machines

- Freshwater treatment used for cooling

Water and Waste Water Treatment

- Protective filters ahead of membrane systems

- Service water conditioning

Automatic Back-Flushing Filter AutoFilt® RF7

The AutoFilt® RF7 from HYDAC is a self-cleaning automatic back-flushing filter with a space-saving, horizontal design. Its pivoting lid allows for easy access inside the filter. This fully automatic back-flushing filter is ready-to-operate, particularly in systems with limited space. Its conical filter elements improve efficiency in separating solid particles from low-viscosity fluids. Automatic back-flushing is triggered by exceeding the differential pressure trigger point, using a set timer, or manually pressing the “Test” button.

Industry Example

Application Example

Power Plants

- Industrial water conditioning

- Sealing water filtration to increase the lifetime of turbine floating ring seals

Steel Industry

- Process water filtration to protect nozzles and pumps used in high-pressure descaling

- Conditioning of water used for cooling blast furnaces and rolling mills

- Emulsion filtration in hot and cold rolling mills

- Rolling emulsion filtration