New Demands Require New Technology

Historically, machine systems have been designed to operate continuously at maximum performance capacity, even though it was required for a portion of each cycle. Today, increasing energy prices and workplace environmental regulations have engineers rethinking their designs and focusing on systems that reduce energy consumption and factory noise. Sytronix servo-driven, pump-drive systems address these challenges. Sytronix variable-speed pump drives combine the reliability of high-performance hydraulics and the energy efficiency of powerful drives and electronics systems.

What is Sytronix?

Sytronix is the abbreviation for: Smart interplay of Hydraulics and Electronics, x. Sytronix is a servo-driven pump drive system that delivers demand-oriented volume flow, provides closed-loop control of pressure, volume, position, and force, and limits the pump consumption.

The Benefits of Sytronix

Noise

Level

- Noise emission reduction through variable-speed-reduced motor noise

- Cost savings due to less sound insulation

- Better compliance with industrial health and safety (OSHA)

- Higher employee satisfaction

Energy

Efficiency

- Energy savings of 30-80% through demand oriented flow and pressure supply

- Decrease in CO2 emissions, reducing carbon footprint

Machinery Lifetime

- Reduction of friction losses leads to longer life time of bearings

- Less heat input into the oil results in better oil quality and longer life time of components

Reduced

Footprint

- Achieve a more compact system design by optimizing the utilization of motors, pumps, and reservoirs

- Potential to downscale or eliminate hydraulic cooling systems, conserving space and resources

Easy Integration

- Flexible control functions easily integrate into system

- Advanced diagnostics and condition monitoring help avoid cost intensive machine failures

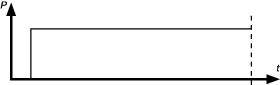

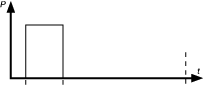

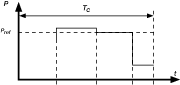

Continuous Duty

The motor operates at a continuous level for the time required to enable a machine to reach thermal equilibrium

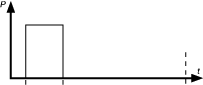

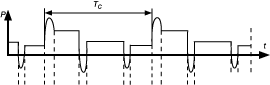

Short Time Duty

The motor operates with a load for a period of time too short to reach thermal equilibrium, proceeded by sufficient time for the motor to cool down

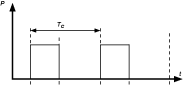

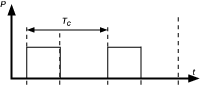

Intermittent Periodic Duty

A sequence of matching duty cycles (constant loads) followed by a rest period. The machine does not reach thermal equilibrium.

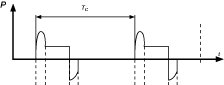

Intermittent Periodic Duty with Starting

A sequence of matching cycles followed by a rest period. The machine has significant starting time and does not reach thermal equilibrium

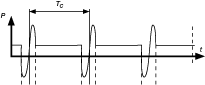

Intermittent Periodic Duty with Electric Braking

A series of matching cycles—start, operate, brake, rest. The machine does not reach thermal equilibrium

Continuous Operation Periodic Duty

Matching duty cycles with a period of load and without load. Motor runs at no-load without stopping

Continuous Operation Periodic Duty with Electric Braking

Matching duty cycles with a period at load followed by a period at no load with significant starting and electric braking periods

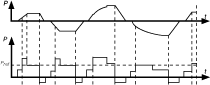

Continuous Operation Periodic Duty with Related Load/Speed Changes

A sequence of repeating duty cycles where the motor runs at different load levels and speed within each cycle. The machine does not stop or reach thermal equilibrium

Duty with Non-Periodic Load and Speed Variations

The machine load and speed differ within an allowable range

Duty with Discrete Constant Loads and Speeds

Duty cycles with balanced load/speed combinations sustained long enough to reach thermal equilibrium

Always the Right Sytronix System

DRn

Perfectly suited for retrofitting existing systems, as most DR and DRG pumps can be used. The DRn system produces an approximate power range of 4 kW (5 hp) and up. The system distinguishes itself with its good dynamics and high overload capacity. The pump independently controls the necessary pressure, and the frequency converter automatically determines the load and sets the perfect speed for the operating point.

At a Glance:

- 4 to 160 kW

- High overload capacity

- High control quality

- Medium Dynamics

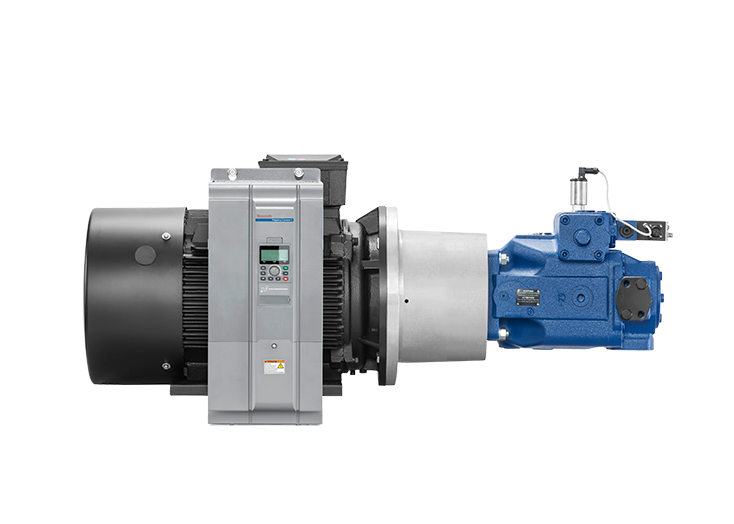

SY(H)DFEn

Also suitable for retrofit in existing systems and applications with high performance demands on dynamics, performance and control quality. These systems employ axial piston pumps with variable flow and variable pressure.

At a Glance:

- 18.5 to 315 kW

- Optional HFC

- Multiple pumps

- High dynamics

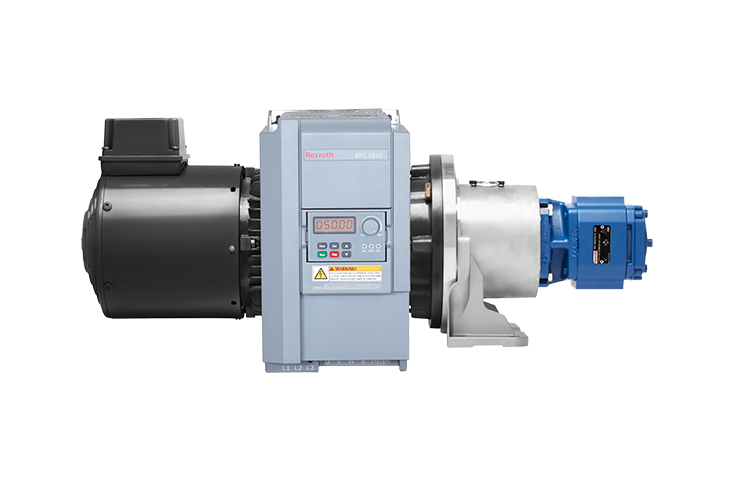

FcP

Suitable for applications with constant pressure, controlled flow profiles or flow with pressure override p/Q controls. The FcP system consists of a motor-pump unit with a standard asynchronous motor and a controller. The FcP product family covers the standard field performance – dynamics, precision and scope of functions.

At a Glance:

- 0.25 to 18.5 kW

- Very low noise level

- Standard dynamics

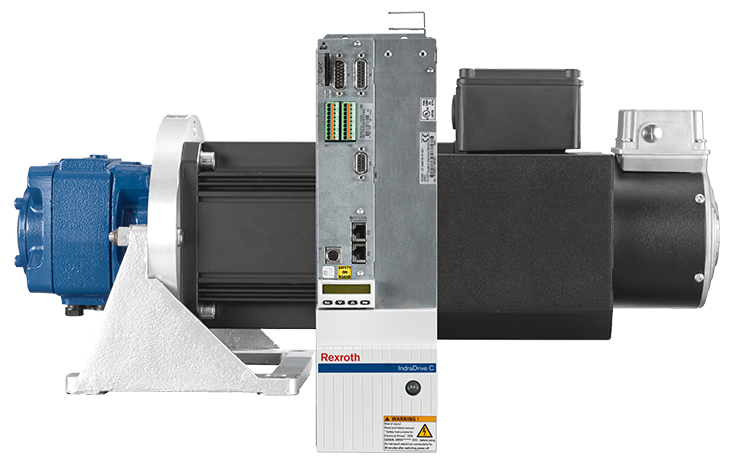

SvP

Partners well in plastics machines and press lines sectors. SvP systems achieve significant energy savings through the use of the high dynamics of servo motors (performance magnets). Their capabilities include advanced electrical and electrohydraulic controls as well as axis control functions in both open and close hydraulic circuits requiring high dynamic performance.

At a Glance:

- 9 to 80 kW

- Position control

- Pressure and flow control

- Very high dynamics

Individual Sytronix Solutions

Apart from the pre-configured systems of the series FcP, DRn, SY(H)DFEn as well as SvP, the Sytronix product range also offers individual solutions. These systems can be planned and configured by combining modules and individual components in collaboration with Evolution.

Compact axis

With Sytronix, you can implement compact and tankless axis solutions

Energy Storage

Energy storage via a capacity on the DC bus or a flywheel mass leads to downsizing of the drive system and to a reduction of power peaks

Master-slave

With master-slave, intelligently connects drive systems can cover higher power

2-point control

The use of axial piston pumps with 2-point adjustment enables downsizing of the drive system

Hydraulic Gear

The use of axial piston pumps with stepless adjustment enables downsizing of the drive system